Production

Production

Our continuing effort to achieve the best in design and technical innovation has enabled us to manufacture our universal joint cardan shaft product line with outstanding features and performance at the highest quality level.

Our product strengths include:

Advanced engineering:

We use 3D modelling and FEM analisys softwares.

Prolonged Bearing Life:

Unique designs for bearings sealing and auto-centring of cross assemblies to ensure optimal lubricating conditions.

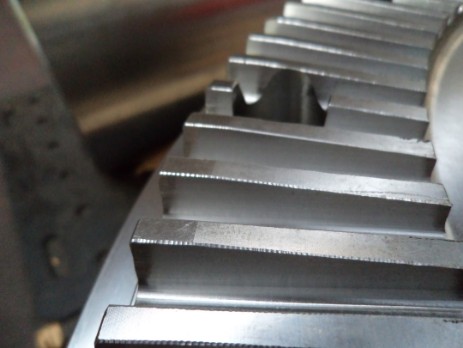

Superior Machining Precision:

Spline sets are precision machined with a unique hobbing-broaching process. The spline surface is also hardened to ensure the accuracy and durability of the transmission are enhanced. The customer can choose between involute or rectangular tooth profiles for the splines.

Production of dedicated components:

In addition to the production of standard components, we have added the production of special components, obtained by forged raw material and with special design, engineered for the specific needs of the client's application.

Anti-vibration system:

In addition to the balancing has been very important the elimination of the movement that can be generated by the tolerance between the teeth of the shaft and sliding tube. This movement generates vibrations harmful to the elements connected to the transmission, for this reason, we have introduced a system to guide the outer tube which runs with a tolerance of 0.1 mm as standard up to our size 315. To achieve this result. all components must be perfectly aligned to the central theoretical axis of the cardan shaft. the advantages can be summarized as keeping clean, vibration cancelling and balancing perfectly even at high rotation speeds.

Optimal Balancing Quality:

Through research into vibration engineering, investment in state-of-the-art manufacturing technology and dynamic balancing techniques EPR has developed cardan shafts that work extremely well at high speeds. Furthermore, welded shafts are tested using Ultrasonic equipment and ensure the standard grade G16 According DIN ISO1940 balancing level. Even balancing grades with higher precision is available on demand.